How to Tackle the Global Supply Chain Crisis

For more than 50 years, Davos, the annual meeting of the World Economic Forum, has been an important barometer of economic, political, social, and environmental issues affecting the future of the world. Speakers at the 2022 Davos summit range from Ukrainian President Volodymyr Zelensky to David Beasley, executive director of the United Nations World Food Program. So, what topics are driving the agenda for Davos 2022? One of them: the global supply chain crisis.

How Davos Is Talking about the Supply Chain Crisis

The global supply chain crisis has taken on a new meaning. As the pandemic spread rapidly in 2020 and lingered in 2021, the general consensus was that disruptions to the global supply chain would be temporary albeit costly. But in 2022, it is clear that fragile supply chain may exist in a perpetual state of disruption for quite some time. In fact, the global supply chain was always in a fragile state; the pandemic laid bare just how vulnerable it was all along.

For instance, global supply chains have always been over-reliant on ocean freight, which is a fundamental problem that predates the pandemic. A lack of alternatives to ocean freight has strained the global supply chain to its limits. Once accident or interruption can completely upend the entire global shipping network, similar to how a lane closure on an already-congested highway can cause interminable traffic delays.

Well, the pandemic gave us that interruption – not once, but many times over. Surges in the pandemic have caused entire ports to shut down, causing massive back-ups with ripple effects all over the world. Global economic markets, already wobbly, have been affected.

And in 2022, the disruptions continue, including a war in Ukraine that has threatened the world’s supply of wheat. This was a point stressed by Frank Appel, CEO Deutsche Post DHL Group, who said, “The war in Ukraine and the pandemic-related lockdowns in Shanghai have revealed how local supply chain disruptions can become global issues. But we needn’t only look at these recent events. A cyberattack on a key player, a blocked canal, a volcanic eruption – we have seen several cases over the years that severely stressed supply chains.”

He noted that to counter this problem, leaders need to reshape supply chains to become more immune to single source disruptions, such as by multi-sourcing of suppliers, or using multiple trade lanes and modes of transport. In addition, they need to address the increased volatility by building greater agility into their supply chains, such as with digitalization and automation.

Julia White, chief marketing and solutions officer and executive board member, SAP, stressed the importance of data transparency.

“Data transparency is essential,” she said. “By embedding metrics in core business processes that measure climate risk, carbon emissions, and waste and pollution, among others, across both upstream and downstream supply chains, organizations can access a continuous view of financial, social and environmental data that manual processes simply cannot offer. Suppliers are increasingly required to be transparent and verifiable in their fair and equitable labor practices. As new legislation requires organizations to more consistently and systematically address human rights issues, business leaders need data-based monitoring and validation mechanisms across an organization’s entire value chain.

Our Take: AI + Third-Party Data Are Essential

We believe that the supply chain crisis is an opportunity for businesses to transform their supply chains, fueled by artificial intelligence and third-party data. We agree with Julia White: data transparency is essential. But many businesses lack basic visibility into the location of products in the supply chain, and they lack the ability to sense and respond to fluctuations in prices and the movement of goods.

For too long, businesses have managed their supply chains with platforms and solutions strung together haphazardly. As a result, enterprises have planned blindly, with too many data blind sides due to lack of visibility and data capture mechanism across the value chain. They’ve also being and be too reactionary because of planning inefficiencies, which leads to the “bull whip effect” -- or the demand distortion that reverberates throughout a supply chain from the retailer through to the wholesaler and manufacturer due to the variance of orders which may be larger than that of sales.

How AI and Third-Party Data Can Help Businesses Transform Their Supply Chains

AI is crucial to achieving long-lasting changes to the way businesses manage their supply chains. Two examples stand out:

- Visibility in real time: with real-time data, a business can identify the status of inventory across the entire supply chain. Many businesses are suffering because they lack data about what is on a ship transporting their materials. They need to know where their goods are at all times to sense and respond to changes in demand and supply. This is especially true of complex supply chains that rely on many players operating globally. But a lack of transparency makes it nearly impossible for them to take steps such as identifying how to predict when inventories might return to normal.

- Forecasting: AI can help a business simulate and forecast the impact of supply-side issues on the demand side. AI can help businesses conduct scenario planning exercises and inform critical business decisions. we suggest that businesses use the current disruption as an opportunity to put in place a disaster management program driven by artificial intelligence/machine learning. AI-based scenario planning helps manufacturers do a better job responding with resiliency by anticipating shortages and supply issues ahead of time and then responding with resiliency strategies. This would require having the data and be able to simulate resiliency responses. AI could also help businesses along the supply chain predict if a particular disruption (such as a natural disaster) is transitional or longer term and simulate response scenarios based on that data.

But businesses need to carefully apply AI. AI also needs real-time, third-party data to guard against the trap of relying on historical data that loses its value as real-time conditions change.

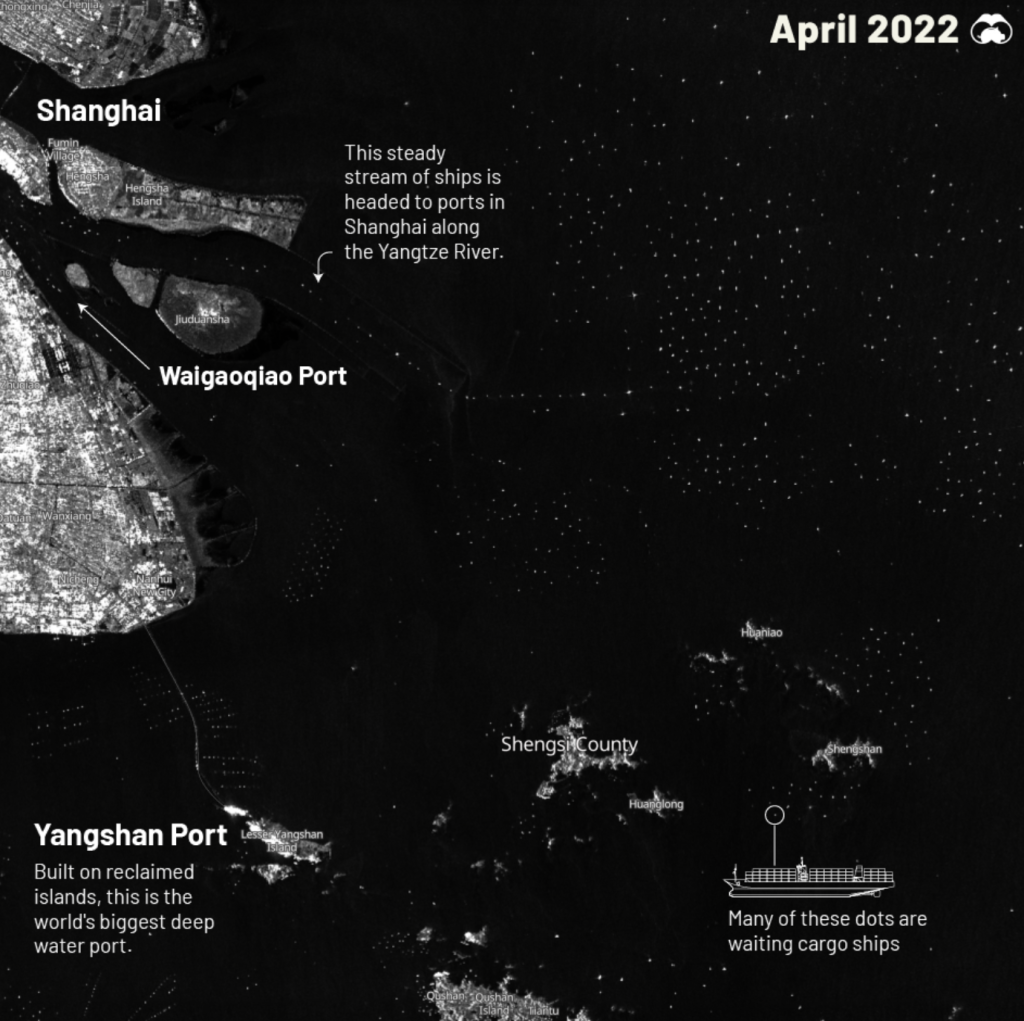

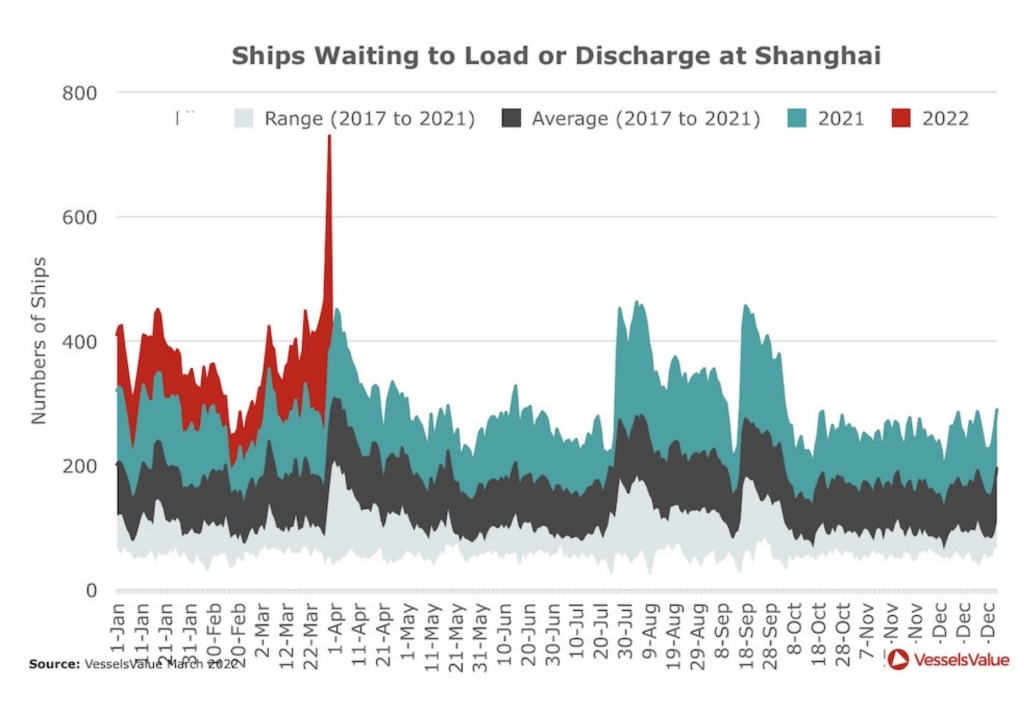

Third-party data such as weather forecasts and satellite maps of port traffic give companies a real-time snapshot of conditions that can affect supply chain operations. For instance, third-party data about shipping lanes (obtainable from aviation intelligence companies) vividly illustrates the scope of a supply chain disruption that flared up in Shanghai in 2022:

Third-party data gives, say, a retailer in the U.S. more granular visibility into the probable impacts of how the congestion will slow down cargo ships that require a few weeks to reach their destinations in U.S. ports. From there, the retailer can more accurately estimate the impact on supply over a period of weeks and months, and adapt its forecasts accordingly. Merchandisers can more effectively weigh the impact on costs and pricing strategies.

Even better, retailers can combine third-party shipping and weather data with consumer-generated data such as Google search trends to align supply more precisely with demand (always a moving target) at regional levels. They can weigh this information against their own first-party data on inventory levels and customer purchasing patterns. A supply chain crisis does not affect every region of the U.S. in equal measure. A shortage of rain-repellant clothing is going to have more of an impact on retailers in Seattle in the summer than it will retailers in Phoenix.

No human being can possibly monitor, assimilate, and analyze this data at scale. To do so, businesses need to apply machine learning, a form of AI. With machine learning, businesses can shift through third-party data and find patterns and associations that would go undetected by manual means.

Summary

No one can “solve” the supply chain crisis, at least alone. There are deeper structural problems that need to be addressed, as we’ve pointed out here in our example of the over-reliance on cargo ships operating in a limited number of lanes. But businesses can lessen their impact with better data and better visibility.

We help organizations make smarter decisions that account for constantly changing variables, such as shifts in consumer demand and disruptions to supply. Our future-proof forecasting platform, Meerkat, allows businesses the scenario plan with clarity and confidence by leveraging state-of-the-art, pre-trained AI models, fueled by an extensive data ecosystem, and interactive decision-making tools.

Our solutions allow organizations to jumpstart better decision-making by rapid creation and deployment of enterprise-grade platforms that leverage their current technology investments.

To plan for disruption and grow your business, contact Centific.